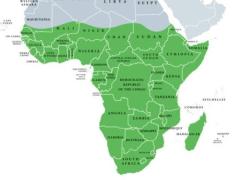

Supply-chain disruption has become a permanent feature of global trade, with companies in Sub-Saharan Africa (SSA), the Middle East and North Africa (Mena), and the Gulf Cooperation Council (GCC) facing the most severe consequences in downtime, costs and reputational damage.

This is according to a new global report, Without Logistics, released by DP World, which is based on a survey of 680 senior logistics and supply-chain decision-makers across eight industries and nine regions.

It concludes that disruption is no longer episodic but a structural reality.

“Disruption is now entrenched but its impact is uneven,” the report says, adding that firms in SSA, Mena, and the GCC are “suffering the longest downtime, highest costs and most severe reputational fall-out”.

Key data underscores the disparity.

In SSA, 83% of firms report losing more than a month of operational time annually due to major disruptions, compared with 72% in Mena and 61% in the GCC. In contrast, only 50% of North American firms, 41% in Germany and 36% in the UK face similar losses.

The financial impacts of disruptions are equally pronounced. Nearly half of companies in the GCC (47%) and more than four in ten in Mena (43%) report annual disruption costs of $1 million or more.

“Most companies report losing more than a month of operational time each year and in many cases, the cost of a single incident runs into hundreds of thousands of dollars. Some companies face disruption losses exceeding 1 million US dollars annually,” the report said.

“Disruption is more frequent and more costly in the Global South. Many of these regions are also investing more ambitiously in logistics modernisation.”

Additional pressures include reputational harm, with high levels of customer complaints, lost contracts and damaged trust in affected regions. The report highlights that “across sectors and regions, supply chain disruption continues to threaten time, cost and performance”.

“Supply chains are facing more disruption, more often. From port congestion and border delays to extreme weather and geopolitical tension, pressure is coming from multiple directions. Many organisations are still responding far too late,” the report noted.

The company’s latest study builds on its Without Logistics series, quantifying costs and identifying resilience strategies.

“Business leaders agree that resilient supply chains will be critical over the next three years. The focus now is on how to get there,” it adds.