Fears over the impact of the

massive refurbishment

project at the Port of

Durban have been allayed

as contingency plans are proving to

be successful.

According to Roy Ramdiyal,

regional manager for Safmarine

in KwaZulu-Natal, Swaziland

and Botswana, there were serious

concerns over the loss of quay

space at container terminals

1 and 2 where deepening and

strengthening had to take place

and what the impact would be on

operations.

“The plans put in place during

the upgrades so far have been

working very well and the effect

of the renovations has not been

as bad as was expected,” he said.

“No doubt the lower container

volumes over the first quarter of

the year played a role in this, but

the introduction of additional

equipment, new straddle carriers

and increased labour resourcing

has assisted in improving

productivity.”

Efficiency at the Port of Durban,

however, remains one of the

greatest challenges.

Due to its configuration and

location, Pier 1 is a particularly

high focus area.

“It is the most susceptible to

wind delays and congestion,” said

Ramdiyal. “Regular meetings are

held with the port management

to understand the constraints and

assist wherever possible to mitigate

delays and

congestion. An

example of this

is the recent

discussions

between the

port, shipping

line and

the Citrus

Growers’

Association

regarding

the improved

productivity

for export reefer containers that

has resulted in the port deploying

reach stackers to handle reefer

containers at Pier 1.”

Ramdiyal said it was essential

that stakeholders in the port

worked together to ensure

productivity remained high as it

was not only the responsibility of

terminal and port operators.

“Shipping lines also play

an important role in keeping

port congestion and delays to a

minimum by ensuring they meet

their berthing windows and

provide the port

with as accurate

as possible time

of arrivals and

operational

information to

assist in planning.”

He said in this

regard Safmarine

had deployed

staff alongside its

vessels, matching

the port shifts, to

assist and monitor

the productivity for improved turntimes

of their vessels.

“Our customers can also assist in

improving the port’s performance

through better utilisation of

the import free time and export

stacking period ie, by also using

the 1st and 2nd free stack days and

accepting or delivering outside the

usual office hours.”

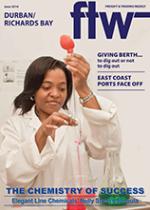

INSERT & CAPTION

Our customers can also

assist in improving the

port’s performance through

better utilisation of the

import free time and

export stacking period.

– Roy Ramdiyal

CAPTION

Improving turnaround time … Safmarine has deployed staff alongside its

vessels, matching the port shifts, to assist and monitor the productivity.