Average waiting time for a berth reduced to 24 hours

A number of systems

put in place by

the Maputo Port

Development

Company (MPDC) are helping

to reduce the overall costs

of using the harbour, says

commercial director Johann

Botha.

“One of the biggest

advantages is that we have

reduced the average waiting

time for a berth to 24 hours,” he

says.

A f lexible berthing policy

means that vessels are berthed

as close as possible to the

storage area of the commodity

they are taking on.

“Where necessary we will

move the cargo to the vessel in

order to minimise delays,” he

says.

Loading efficiencies on the

quayside will be improved

through the addition of two

mobile cranes which are due to

be commissioned in October.

Operators for the Liebherr

cranes have already been

trained and certified.

“When we start operating in

October we will have enough

fully trained staff to operate the

cranes,” he says.

Liebherr units were selected

because of the support available

from South Africa – “spares are

just six hours away by road”.

Productivity is expected to be

high thanks to the investment in

automatic spreaders which lift

an entire container at a time and

then empty it into the hold.

“There will be no people apart

from the truck driver on the

quayside – trucks will drive

up, the crane will lift off the

container, spread the contents

and then put it back on the

truck,” he says.

The result will be improved

safety and savings for the

shippers.

With this system it will be

possible to co-load cargo of

different grades or types into

separate hatches at the same

time.

Productivity is expected to increase

from the present 200-220 tons an

hour to 800 tons an hour.

“We expect to be able to turn a

vessel around in a day and this will

increase the productivity of the

berths,” says Botha.

Further savings for shippers

come from the fact that the MPDC

includes stevedoring in its fees.

“There are also no cargo dues,”

says Botha.

Investment in the road and rail

infrastructure has also improved

efficiencies and reduced the cost of

transporting exports to the port.

The gate entrance has been

reconfigured, and trucks are

routed around the back of the

port so that they do not interfere

with operations.

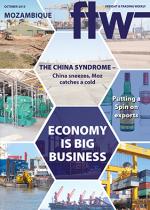

CAPTION

The Port of Maputo ... a flexible berthing policy means that vessels are berthed

as close as possible to the storage area of the commodity they are taking on.